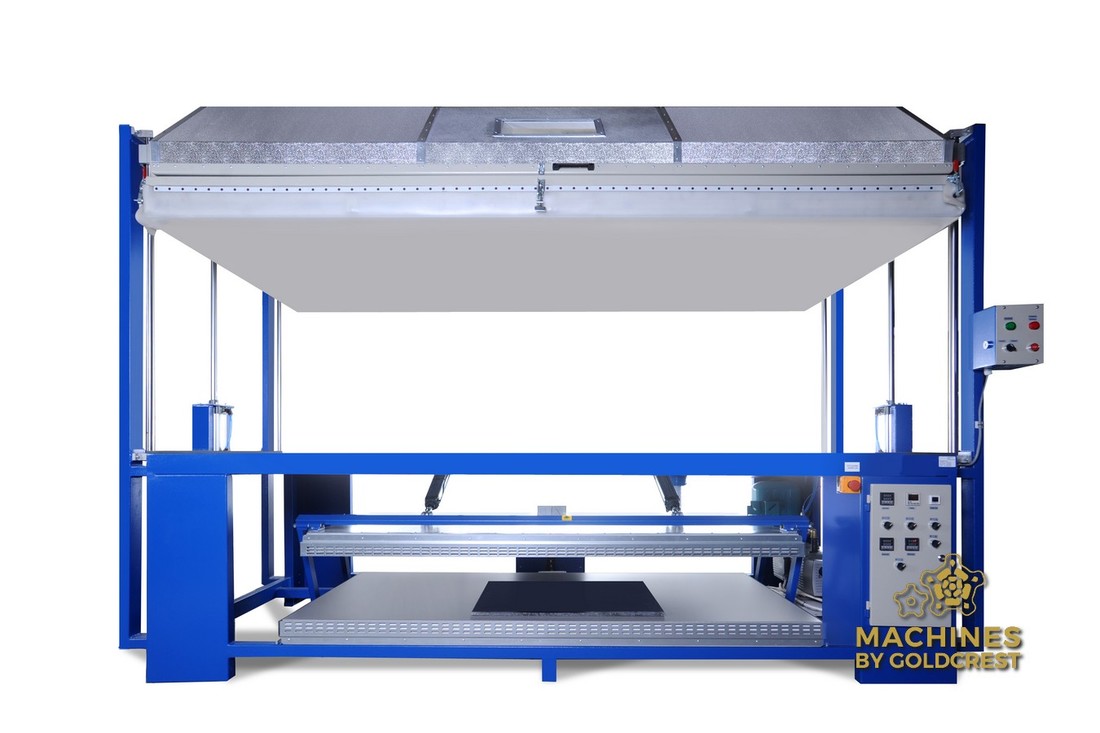

VACUUM PRESSES FOR VENEERING

|

Vacuum veneering press of VPS series is designed for 2D and 3D veneering as well as for wood bending. It is equipped with the

heating system which makes it possible to greatly reduce the bonding time and increase production capacities. It is designed for both small and large manufacturing workshops. ONE SOLUTION FOR:

CONSTRUCTION:

TECHNICAL SPECIFICATION: Working table dimensions (Model 300): 2850 х 1150mm Rubber membrane 700% max temperature: 130 Silicone membrane 800% max temperature: 220 Heater power: 4,5 kW Vacuum pump pressure: -0,75bar Vacuum pump output: 25m3/h Operating vacuum: -0,85_0,90 kg/cm2 (bar) Protection code: IP53 Noise level: < 70 Db Voltage: 3Phase 400 50Hz Outer dimensions: Length - 3150mm Width - 1450mm Height - 1600mm Weight: 550 kg |