FABERTEC M2 12 ATC

CNC MACHINING CENTRE

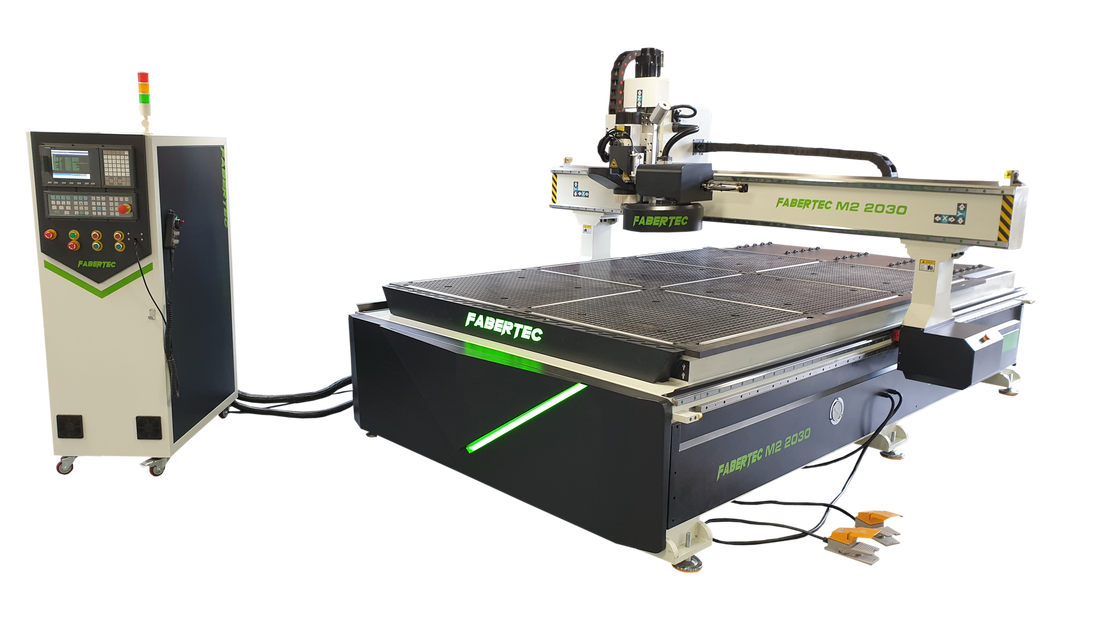

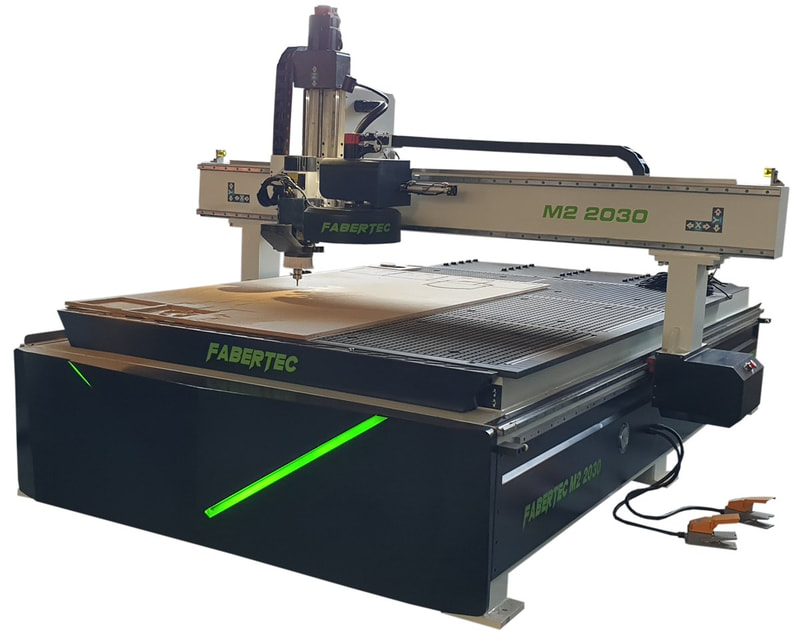

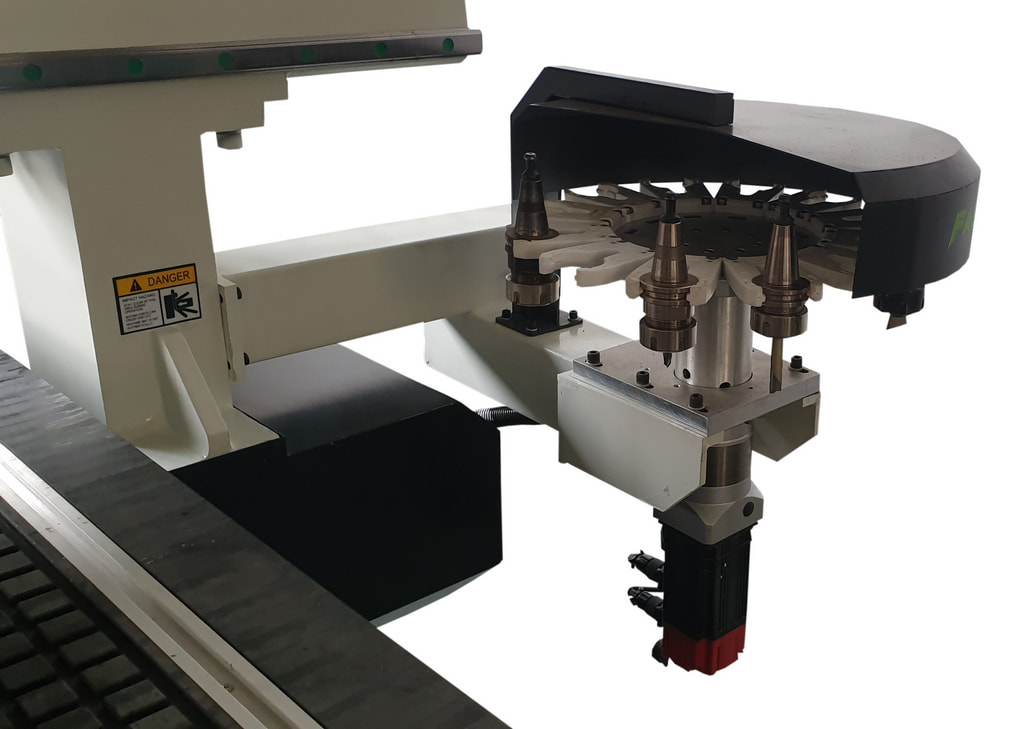

FABERTEC M2 2000x3000 WITH DRILL HEAD

(9 TOOLS) AND 12 REVOLVER ATC

AFFORDABLE PRICES TO GET YOUR WORKSHOP running WITH CNC MACHINE:

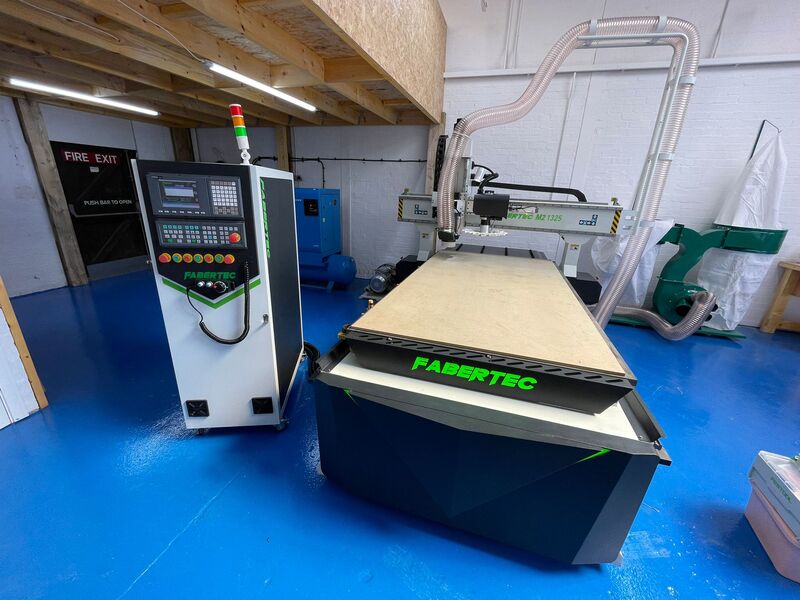

FABERTEC M2 1325 - 1300X2500 12 REVOLVER ATC - £24,500.00 + VAT

FABERTEC M2 1530 - 1550x3080 12 REVOLVER ATC - £26,500+vat

FABERTEC M2 2030 - 2070X3100 12 REVOLVER ATC - £28,500.00 + VAT

LEASE PURCHASE FROM AS LOW AS £120.00 PER WEEK!

FABERTEC M2 ATC CNC CENTRE is a modern machine for the precision machining of materials such as wood, chipboard,

MDF, OSB, plastics, Plexiglas, PVC, HPL, composites (Corian, Hi-Macs, Betacryl etc), dibond, Carbon, alucobond, fabrics, leather, vinyl, soft metals.

This state of the art milling machine is made of thick heavy steel provides high rigidity and resistance to overload, excellent resonance dampening.

CNC machining centre is working in full 3D - you can use it to perform a complete machining in 3 axes for example threads, carving. The M2 comes with free of charge modern CAD/CAM software VCARVE PRO made by local British Milton Keynes company. Our M2 CNC CENTRE together with designing software is equipped with features like: autonesting, automatic correction of the cutter diameter, slope entry into the material, define bridges, automated cutting first internal shapes, visualisation, etc. The program is compatible with all popular graphics programs type Corel Draw, AutoCAD, etc from which you can import your vectors as DXF/DWG files or even 3D objects for carving.

We also supply our Clients with FUSION 360 postprocessor which will allow you to directly create gcode files for processing on CNC.

Main technological aspects which position our CNC machines in line with brands like Biesse, SCM, Format 4, HOMAG but for

a fraction of a price of above brands:

MDF, OSB, plastics, Plexiglas, PVC, HPL, composites (Corian, Hi-Macs, Betacryl etc), dibond, Carbon, alucobond, fabrics, leather, vinyl, soft metals.

This state of the art milling machine is made of thick heavy steel provides high rigidity and resistance to overload, excellent resonance dampening.

CNC machining centre is working in full 3D - you can use it to perform a complete machining in 3 axes for example threads, carving. The M2 comes with free of charge modern CAD/CAM software VCARVE PRO made by local British Milton Keynes company. Our M2 CNC CENTRE together with designing software is equipped with features like: autonesting, automatic correction of the cutter diameter, slope entry into the material, define bridges, automated cutting first internal shapes, visualisation, etc. The program is compatible with all popular graphics programs type Corel Draw, AutoCAD, etc from which you can import your vectors as DXF/DWG files or even 3D objects for carving.

We also supply our Clients with FUSION 360 postprocessor which will allow you to directly create gcode files for processing on CNC.

Main technological aspects which position our CNC machines in line with brands like Biesse, SCM, Format 4, HOMAG but for

a fraction of a price of above brands:

- Firm metal construction, the columns are made from thick 20mm mild steel and gantry from 200x300mm RHS 10mm thick structural element. This allow for lack of any sagging/deformation on even longer gantry for 2000x3000mm table size.

- We always use top brand of runners HIWIN. In the case of M2 we are using heavy duty 30mm trapezoidal runners which can take kinetic loads of 6000kg. As our gantry with spindle weights from 500kg to 750kg you can be assured there is plenty of spare load runners can take so your machine will have the same accuracy after 10 years like a brand new one.

- Rack and pinion are used from German TBI supplier which are very hard wearing.

- Advanced servo drivers and motors which provide high speeds (idle passes and routing), can work longer and what most important they have integrated decoder which constantly checking position of the motor and signal any discrepancy to driver. By being constantly in information loop you can be assured servo will travel to coordinate which operator envisaged and not a 0.001mm further. Speeds of 50 meters per minutes are standard in our M2 machines.

- HQD or HSD - Professional brushless spindle air cooled with automatic tool changer integrated, 9kW always as a standard and with 24000 max revolution per minute.

- 12 Revolver tool changer - Fabertec M2 CNC's are always delivered with 12no of Iso30 chucks so you don't need to invest extra money in any spares.

- Always a vacuum table with air cooled air pump 7.5kW. For smaller elements or tables larger than 1325 we suggest to invest in 2nd pump or one large 11kW rotary vane KVE360.

- Positioning bars on table - quickly move boards into X=0 Y=0 position and start the operation

- Industrial controller SYNTEC with large colour LCD display, pulse generator wheel, all functions clearly marked.

- Gantry height always as standard 300mm for processing higher elements, solid timber slabs etc.

- T-Slots in table to clamp irregular elements which cannot be held on vacuum

- Option of Drill Head with 9 extra tools for drilling purpose

- Emergency sensors at the end of X and Y axis preventing operator from hitting the end buffers. Also as a 2nd safety programable travel limits in Syntec controller. You can be sure damaging our cnc's is not an easy task.

- Centralised lubrication of all runners. Operator doesn't have to worry about keeping up with oiling machine and can focus on more profitable tasks.

- Extra light close to spindle for setting tools, setting datum point etc

- All tool lenghts are measured once and stored in controller so until operator change tool manually he/she doesn't have to worry about tool lenghts in ISO30 chucks

SHORT CLIP SHOWING FEATURES ON OUR FABERTEC M2 CNC CENTRE

TECHNICAL SPECIFICATION FABERTEC M2 1325 ATC

UPGRADED CNC MACHINING CENTRE:

Working Surface: 1300mm x 2500mm

Max Working Height: Axis Z300mm (300mm always as standard at FABERTEC machines - no extra charge)

Motors: All 4 Full Servo Motors with Brake system on Z axis

Linear Bearings: Trapezoidal Tracks 30mm

Speed: 40 m/min (motor capabilities over 60m/min but not advisable to run on such a speeds)

Software Resolution: 0,01mm

Positioning Accuracy: Physical 0,05mm

X Gate Double Motors: Yes

Spindle: 9kW HQD ATC ISO30 air cooled as standard

Spindle RPM: Up to 24000 RPM

Brushless Spindle: Yes

Spindle Tool Diameter: From 1mm to 20mm

Router Bed: Always as standard vacuum bed with T-Slots as standard. Air cooled Vacuum Pump

Weight: 1700 kg (2000x3000 - 2700kg)

External Dimensions: 2300 x 3300mm

Power Supply: 415 V 3 Phase

Max Working Height: Axis Z300mm (300mm always as standard at FABERTEC machines - no extra charge)

Motors: All 4 Full Servo Motors with Brake system on Z axis

Linear Bearings: Trapezoidal Tracks 30mm

Speed: 40 m/min (motor capabilities over 60m/min but not advisable to run on such a speeds)

Software Resolution: 0,01mm

Positioning Accuracy: Physical 0,05mm

X Gate Double Motors: Yes

Spindle: 9kW HQD ATC ISO30 air cooled as standard

Spindle RPM: Up to 24000 RPM

Brushless Spindle: Yes

Spindle Tool Diameter: From 1mm to 20mm

Router Bed: Always as standard vacuum bed with T-Slots as standard. Air cooled Vacuum Pump

Weight: 1700 kg (2000x3000 - 2700kg)

External Dimensions: 2300 x 3300mm

Power Supply: 415 V 3 Phase