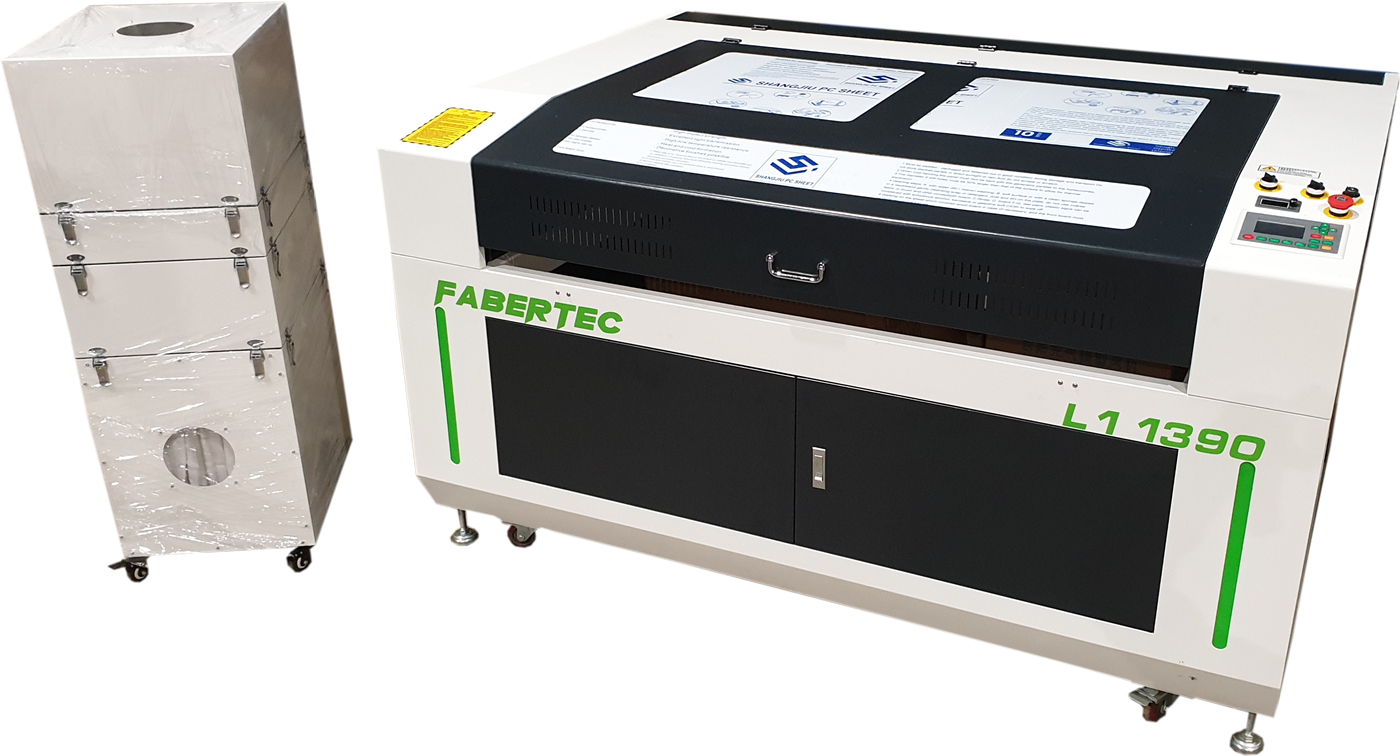

FABERTEC L1 CO2

LASER CUTTERS AND ENGRAVERS

FREE CARBON FILTER WORTH £700.00 FOR ORDERS PLACED

unTIL 31ST DECEMBER 2021!

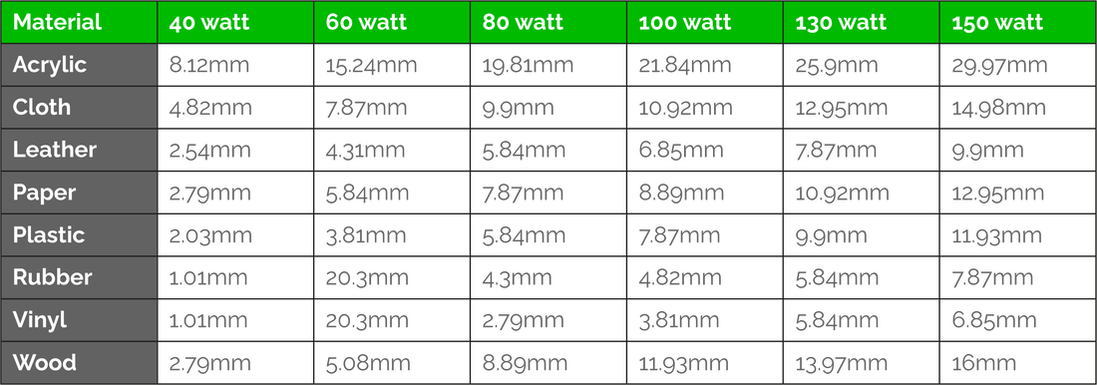

All CO2 lasers using CO2 tubes with different wattage ranging from 40watt to 150watt dependable on material that needs to be cut or engraved.

In our L1 range we mostly start with 100watt (6040 & 6090) laser output to be able to process thicker materials "straight from the box" and not overuse the tubes during operations.

Below is a brief spec of what type of materials we can cut accordingly with laser power.

In our L1 range we mostly start with 100watt (6040 & 6090) laser output to be able to process thicker materials "straight from the box" and not overuse the tubes during operations.

Below is a brief spec of what type of materials we can cut accordingly with laser power.

Please bear in mind that for example, acrylic 19.81mm is a maximum thickness we can achieve using 80watt laser with slowest possible speed of the laser head. We cannot choose future machine for our production looking only at the end scale.

To cut efficiently on the CO2 lasers we cannot use 100% of the power all the time as this will downgrade the tube quite rapidly (from advertised 8-10k hours we will kill the tube to maybe 1000h using 100% of power).

So if you want to cut 19mm acrylic we would advise 100w or even 130w tube to prolong its life and what is also import to achieve a better edge finish due to quicker laser movements.

To cut efficiently on the CO2 lasers we cannot use 100% of the power all the time as this will downgrade the tube quite rapidly (from advertised 8-10k hours we will kill the tube to maybe 1000h using 100% of power).

So if you want to cut 19mm acrylic we would advise 100w or even 130w tube to prolong its life and what is also import to achieve a better edge finish due to quicker laser movements.

Fabertec L1 and L2 CO2 lasers are very easy to operate. A typical operator can be up and ready in literally 1 hour after delivery and installation.

After connecting PC by USB to the L1 or L2 laser the software is ready to work with laser cutter straightaway.

The only options which operator need to familiarise itself with in laser cutting is percentage power of the laser and speed of laser head above the material. That is why it is quite easy to

start with accurate cutting or engraving after 30-60min of testing particular Clients materials

in different thickness.

After connecting PC by USB to the L1 or L2 laser the software is ready to work with laser cutter straightaway.

The only options which operator need to familiarise itself with in laser cutting is percentage power of the laser and speed of laser head above the material. That is why it is quite easy to

start with accurate cutting or engraving after 30-60min of testing particular Clients materials

in different thickness.