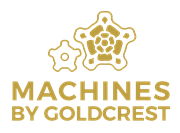

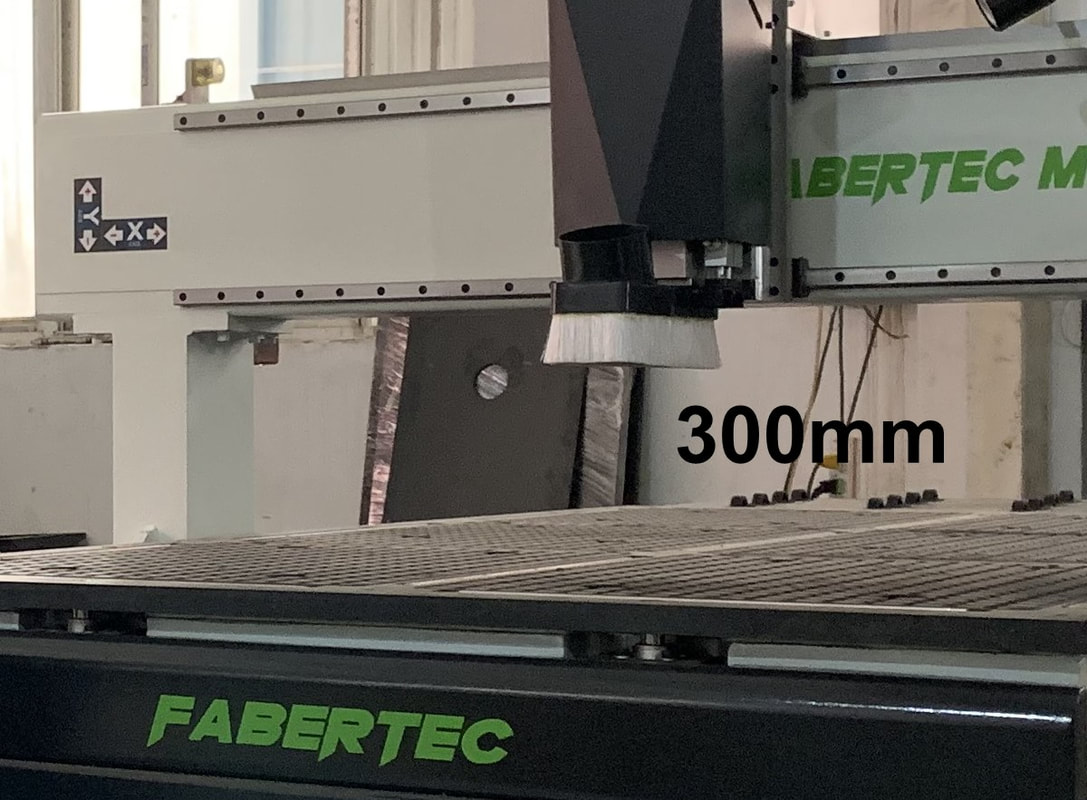

FABERTEC M1 CNC CENTRE

|

Fabertec M1 CNC Router is a modern machine for the precision machining of materials such as wood, chipboard, MDF, OSB, plastics, Plexiglas, PVC, HPL, composites (Corian, Hi-Macs, Betacryl etc), dibond, carbon, alucobond and others.

This state of the art milling machine is made of thick mild steel sections which provides high rigidity and resistance to overload, and provides excellent resonance dampening. The machine is equipped with an intuitive interface having advanced features. M1 CNC machining center is working in full 3D - you can use it to perform a complete machining in 3 axes for example threads, carving. Plotter comes with a modern CAD/CAM program. Our milling plotter software is equipped with functions like: autonesting, automatic correction of the cutter diameter, slope entry into the material, define bridges, automated cutting first internal shapes, visualisation, 3D routing tool path and others. |

VERY AFFORDABLE PRICES TO ALLOW YOU TO SPEED UP YOUR WORKSHOP PROCESSES:

FABERTEC M1 1300X2500 - £14,950.00 + VAT

FABERTEC M1 1500X3000 - £16,950.00 + VAT

FABERTEC M1 2000X3000 - £18,950.00 + VAT

FABERTEC M1 1325 ATC 8 TOOLS CHANGER - £18,950.00 + VAT

FABERTEC M1 1530 ATC 8 TOOLS CHANGER - £20,950.00+VAT

FABERTEC M1 2030 ATC 8 TOOLS CHANGER - £22,950.00+VAT

LEASE PURCHASE FROM AS LOW AS £85.00 PER WEEK!

FABERTEC M1 1325 WITH ATC

SOME OF THE IMPORTANT FEATURES OF THE

FABERTEC M1 CNC CENTRE

|

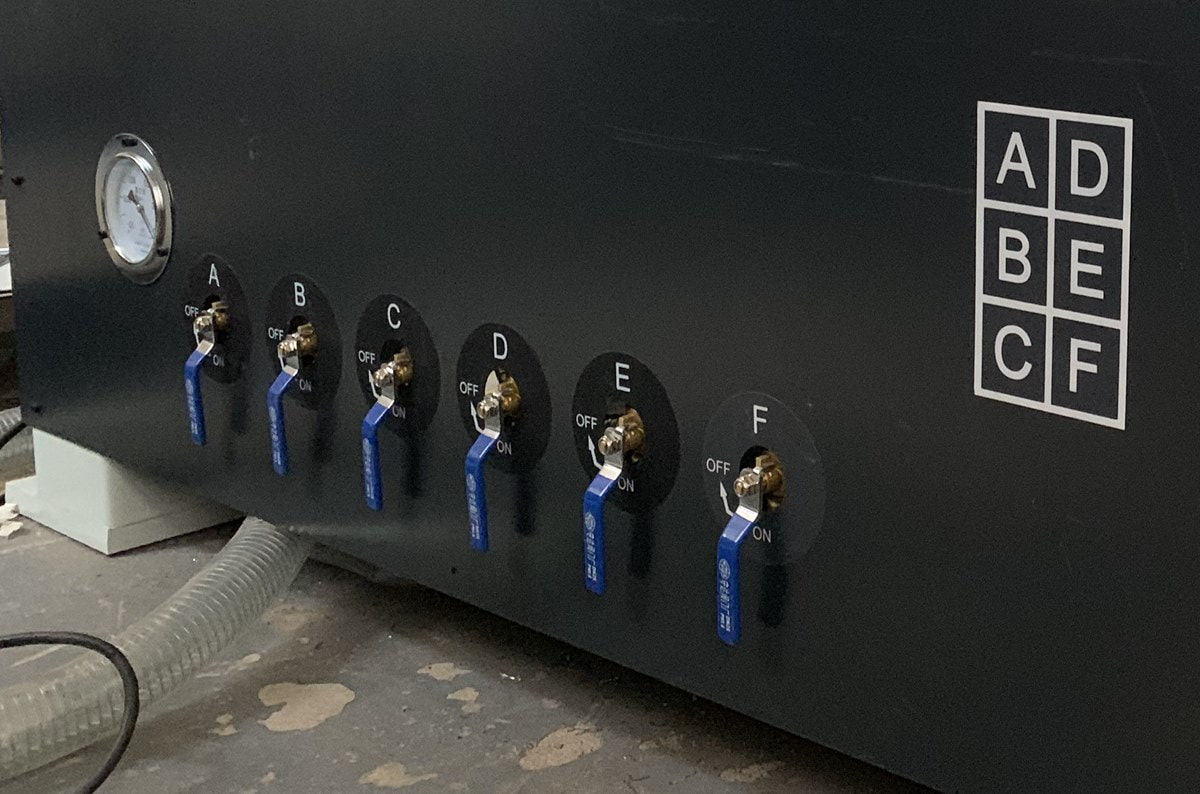

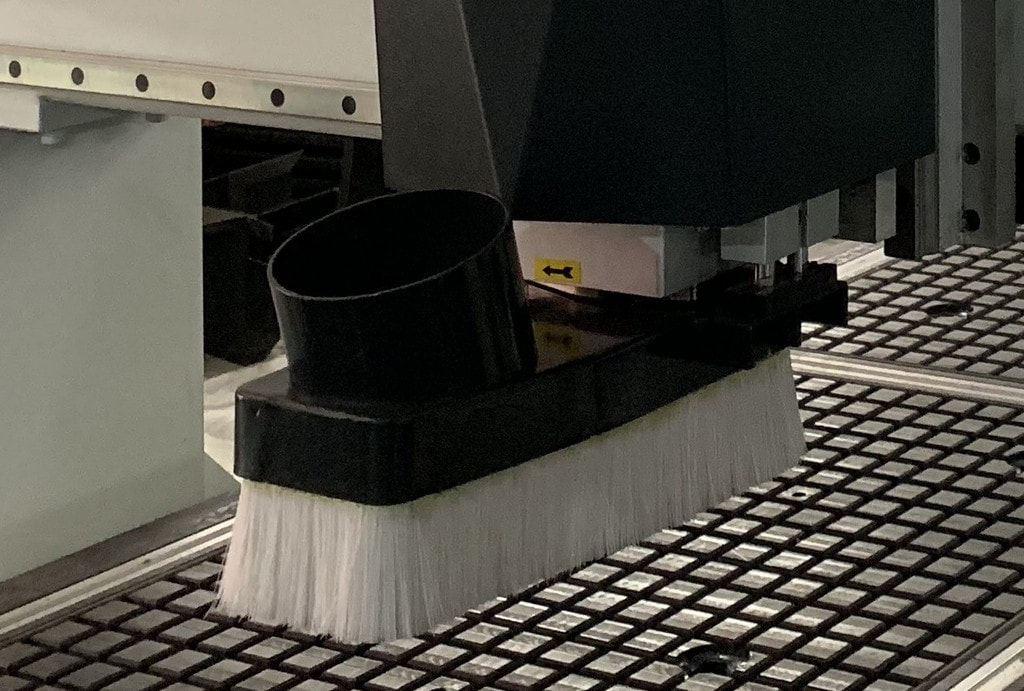

VACUUM TABLE WITH AIR COOLED VACUUM PUMP

T-SLOTS INCLUDED AS STANDARD Quick and efficient work by holding your work piece/board in place by vacuum suction. No need to clamp boards in place saving a lot of operator time. The vacuum pumps supplied by us are always air cooled. The cheapest ones are water cooled and operator has to remember to keep the tank full, use antifreezers in winter, make sure no liquid is left in system during winter if antifreeze not used. |

|

REAL SERVO MOTORS AND DRIVERS LEADSHINE

Servo motors are best motors available for the CNC (and other) machines. A great number of CNC machines are supplied only with stepper or hybrid servo motors. The main difference between SERVOs and other motors is that they have a feedback loop to driver. It means that driver always knows the "position" of the servo motor, if it missed any routing step, if there is too much tension on the motor etc. That allows driver to counteract or inform of any challenges during the processing. |

|

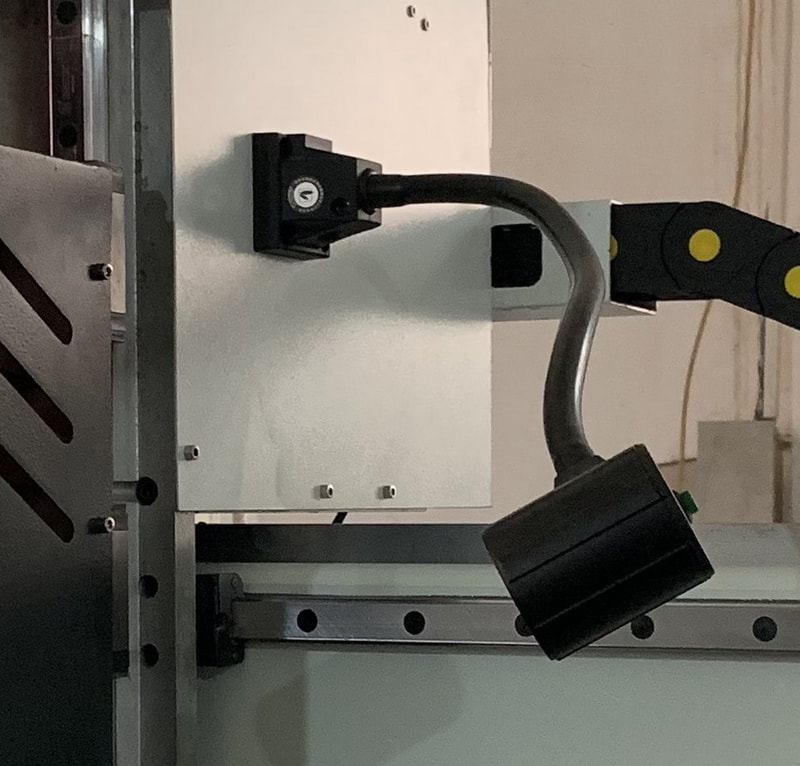

CENTRALISED LUBRICATION

The lubrication oil for all guides/runners is located in automatic pump tank. After a set amount of minutes it will lubricate all guides and runners. By working with machines with manual lubrication we know it was a huge waste of time of the operator hence this option was added as standard. |

|

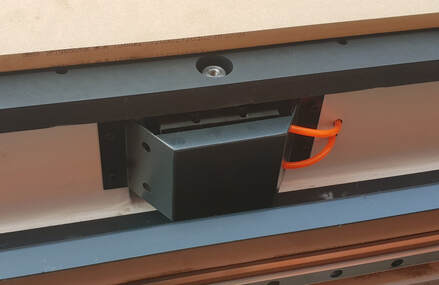

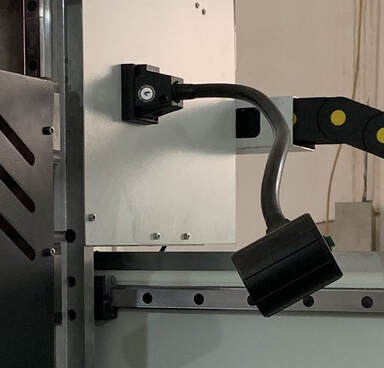

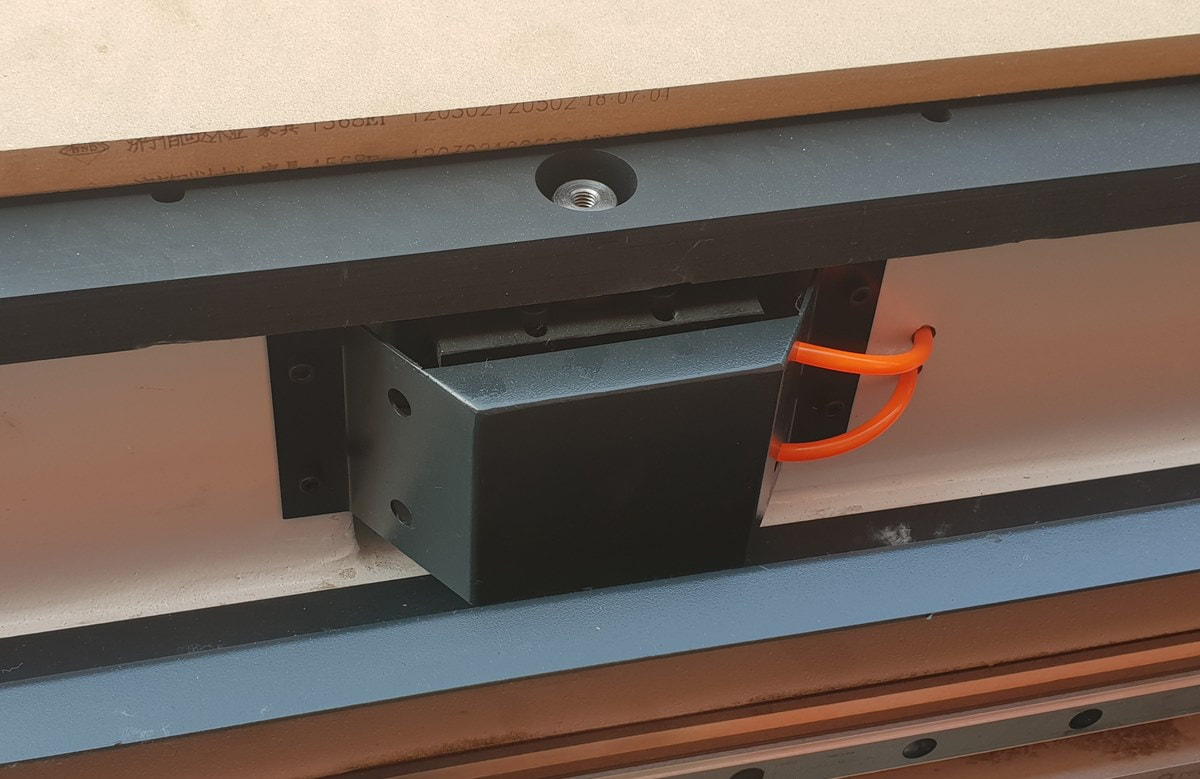

SENSORS AT THE END OF AXIS

They will slow down and then shut down SERVOS close to the end of the axis. Situations happen when operator is moving the gantry too quick by controller and of course machine will follow the instruction. Without those sensors the gantry will hit end buffers and stop with the errors which create a strain on the structure, motors, guide. SENSORS allows machine to KNOW that it is at the end of axis and will shut down MOTORS preventing damage. This is almost not present in cheaper, budget machines from suppliers who never go to Chinese Factory to supervise production, add improvements and sign off shipments. |

|

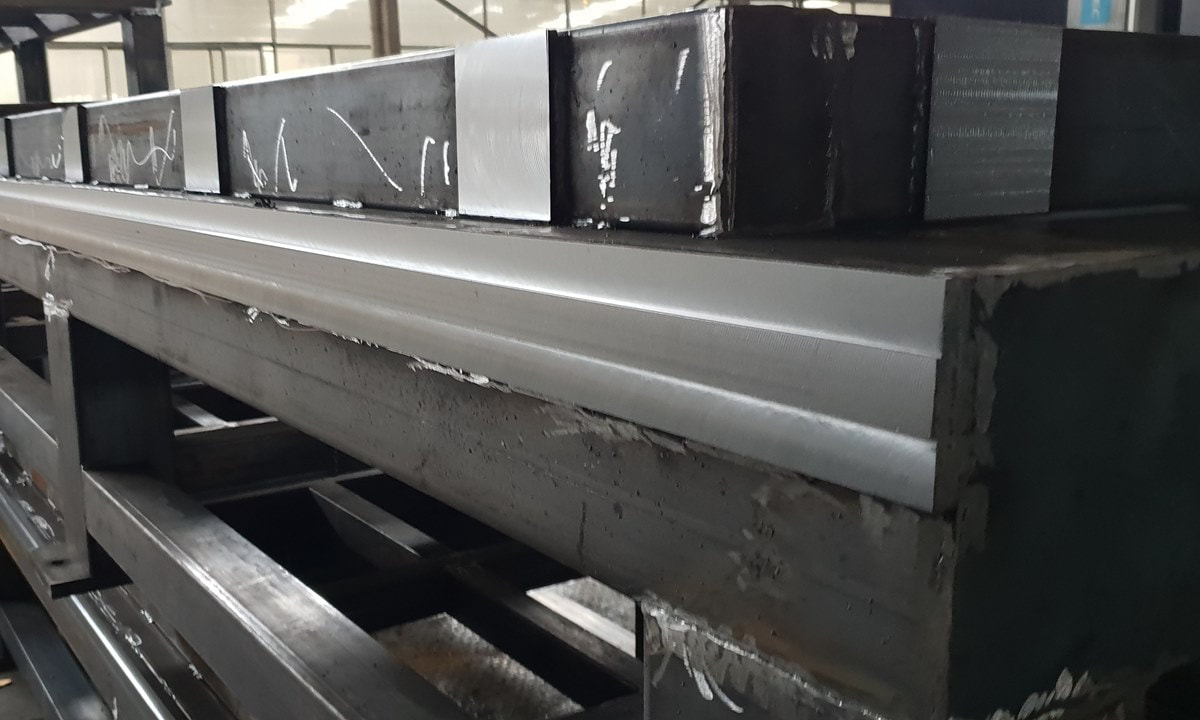

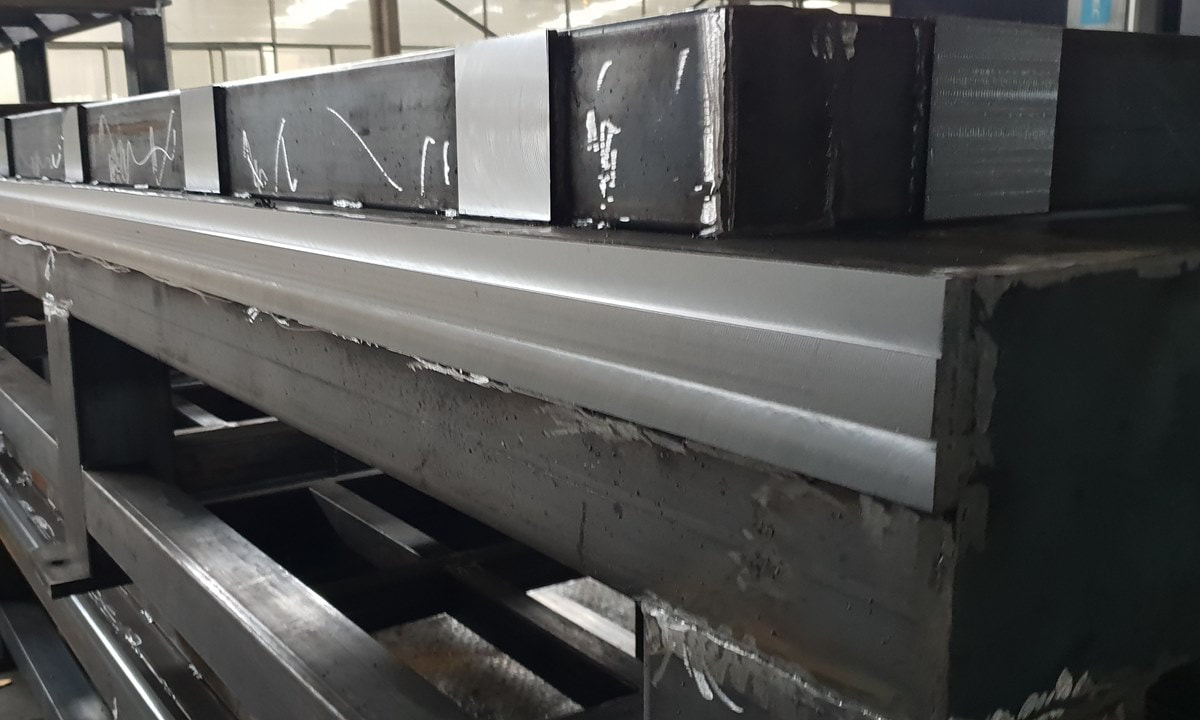

HEAVY DUTY BASE/BED/GANTRY

TAKEN FROM M2 CNC Taken from our more professional machines. Over 300kg more weight compared to the basic model. Much more stable, less vibrations, allows for positioning bolts. All fixing surfaces are milled by 100ton huge industrial CNC machines to make sure every fixing surface is perfectly aligned, square and true. |

CNC comes fully assembled from our UK workshop (1325 version. The 2x3 meters needs gantry installation

at the clients premises). Just levelling, double checks and ready to work.

Full 24 months UK firm Warranty plus another 12 months online/phone support.

at the clients premises). Just levelling, double checks and ready to work.

Full 24 months UK firm Warranty plus another 12 months online/phone support.

FEATURES OF M1 CNC ROUTER

TECHNICAL SPECIFICATION FABERTEC M1 1325 UPGRADED CNC MACHINING CENTRE:

Working Surface: 1300 x 2500mm (Other sizes like 2000 x 3000, 1500 x 3000, 700 x 2500 etc available)

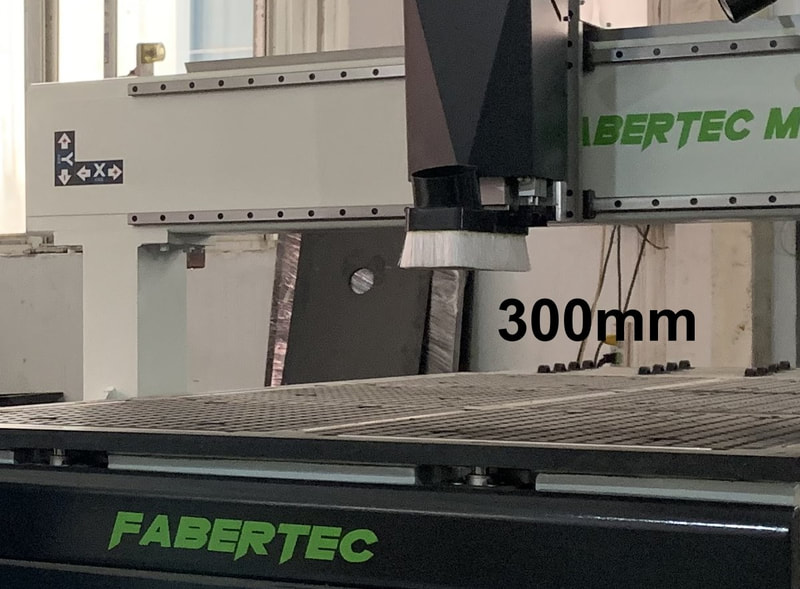

Max Working Height: Axis Z 300mm

Motors: SERVO 850W X, Y, Z Ball screw Axis Z

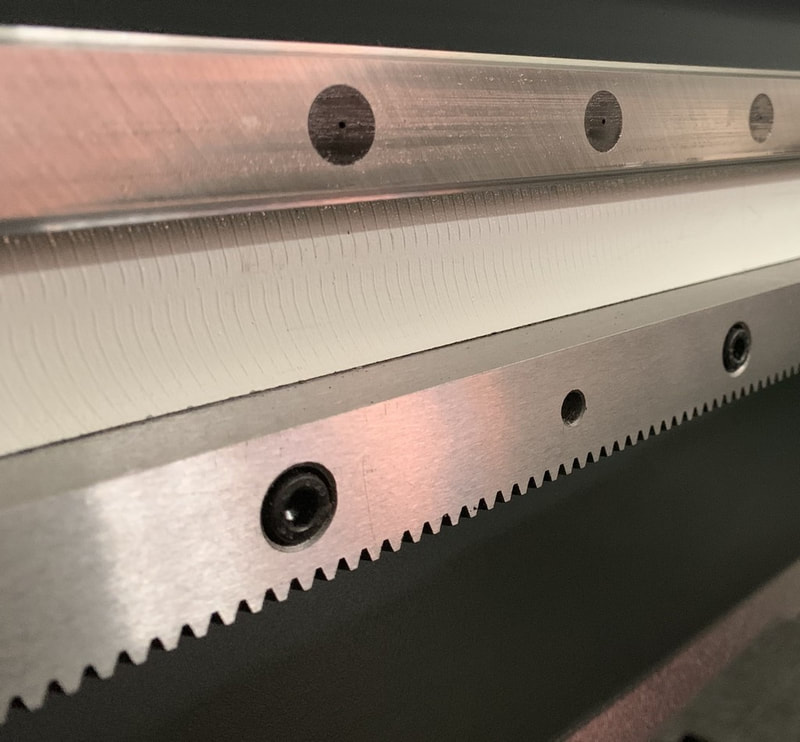

Linear Bearings: Trapezoidal Tracks

Speed: 40m/min

Software Resolution: 0,01mm

Positioning Accuracy: Physical 0,05mm

X Gate Double Motors: Yes

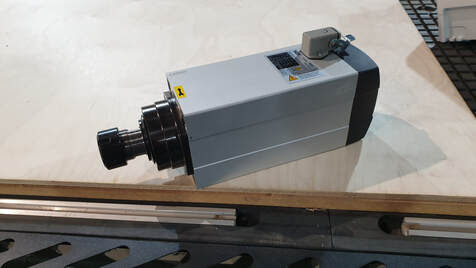

Spindle: 6kW HQD AIR COOLED

Spindle RPMU: Up to 24000 RPM

Brushless Spindle: Yes

Spindle Tool Diameter: From 1mm to 21mm shank. Tool diameter can be even 50-60mm.

Router Bed: Always as standard vacuum bed with T-Slots. Air cooled vacuum pump included.

Weight: 1700 kg (1325 Model)

External Dimensions: 2200 x 3300mm

Power Supply: 415 V 3 Phase 50Hz